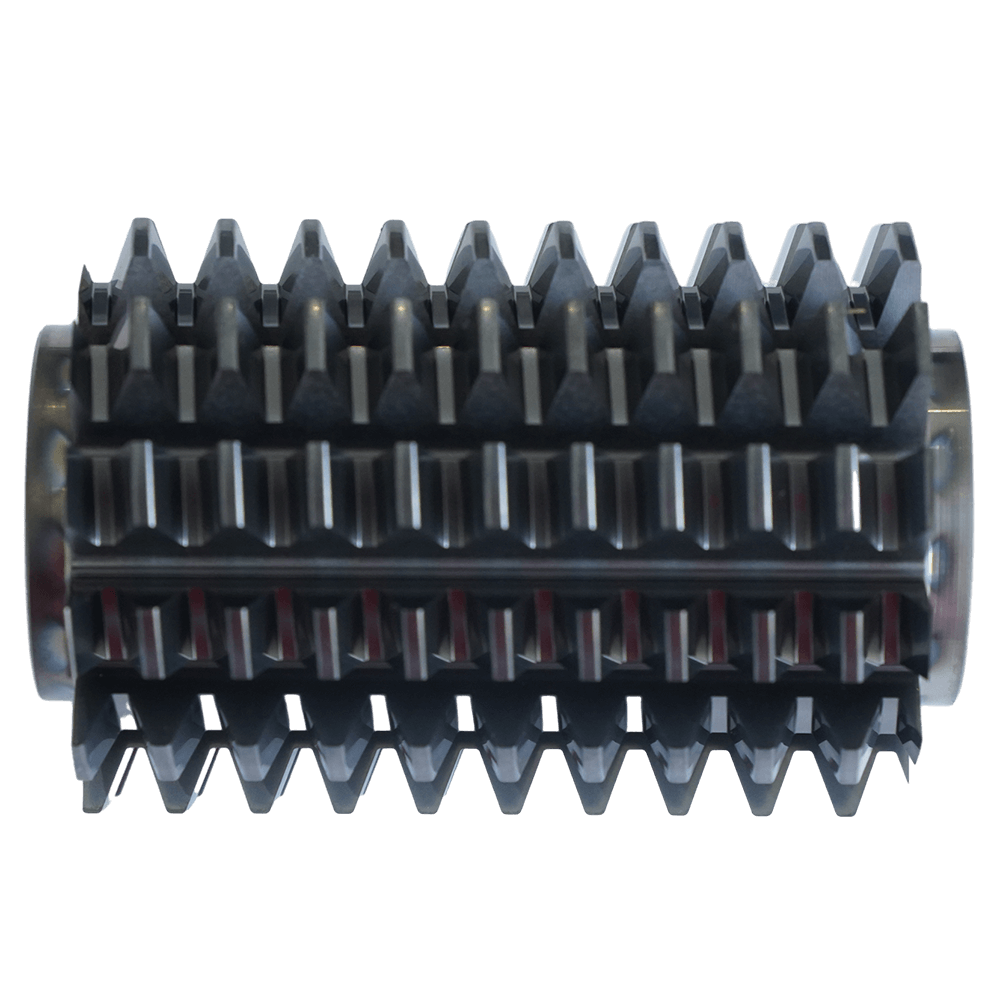

Hard alloy gear hobs

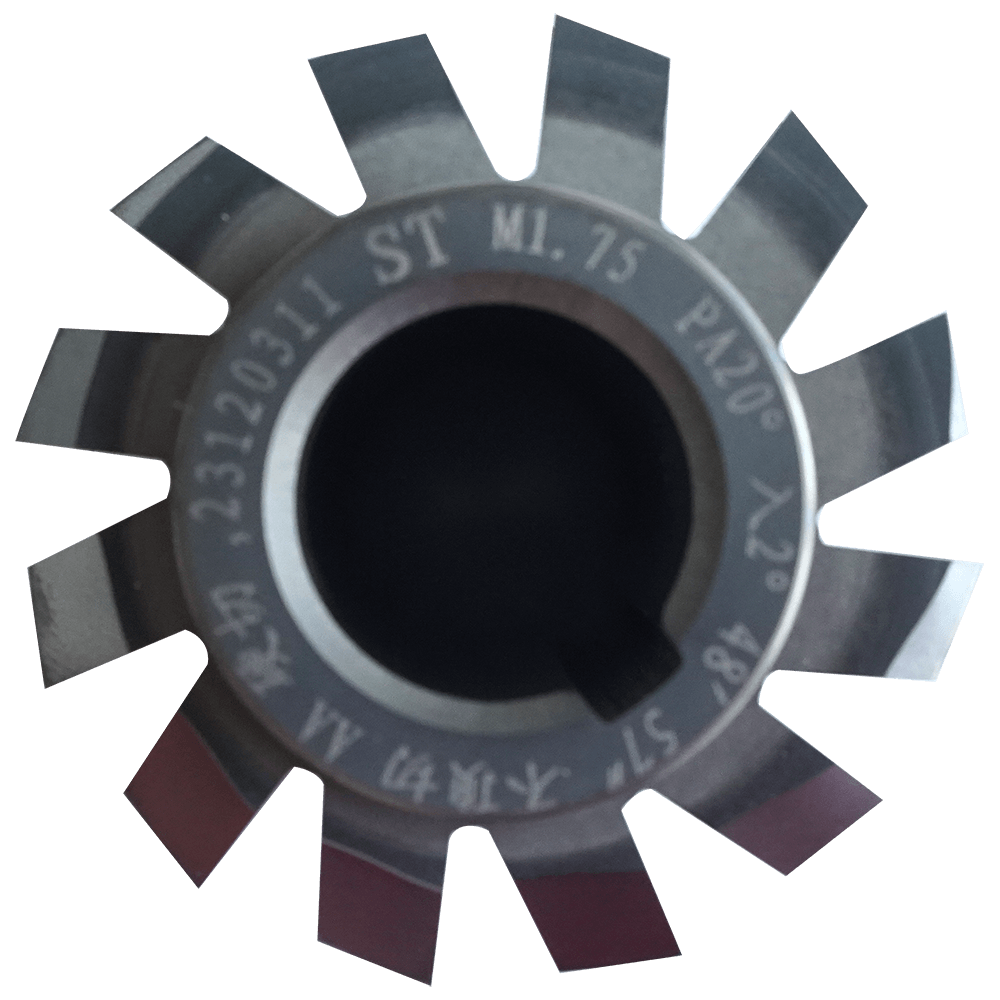

Module: m0.1-m4.5

Outer diameter: ∅8-120mm

Accuracy: AA, AAA (DIN3968)

Coating: Balzas coating

Our company can produce all special requirements of hard alloy hobs, including involute spline hobs, rectangular spline hobs, synchronous pulley hobs, cycloidal hobs, fixed hobs, integrated hobs, worm milling cutters, etc.

Hard alloy hobs are mainly composed of hard phase WC and bonding phase Co, and their teeth are gear machining tools arranged along a cylindrical or conical spiral line. They are widely used in machining cylindrical gears, turbines, and other cylindrical toothed workpieces.

Hard alloy rolling cutters are made of high-performance hard alloy materials, which can be soft rolled before heating and have a significantly longer service life compared to high-speed steel rolling cutters. They can also be hard rolled after heating, and the hardness of hard rolled workpieces can reach HRC50-62, making them the best choice for rolling instead of grinding.